Machining Technology

Projects

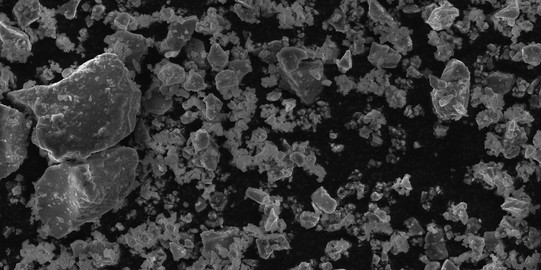

Fundamental Characterization and Analysis of the Lubricating Effect of Quasicrystalline Powders as an Intermediate Medium in the Chip Formation Zone

Approaches to Materials and Manufacturing Technology for Effective Machining of High-Strength Austenitic CrMn Steels

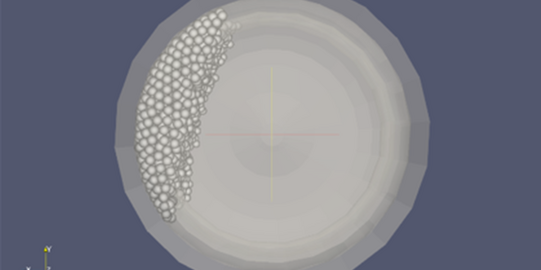

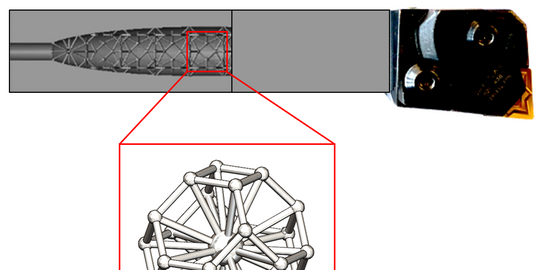

Simulation-Based Development and Experimental Validation of Tool-Integrated Rotary Particle Dampers

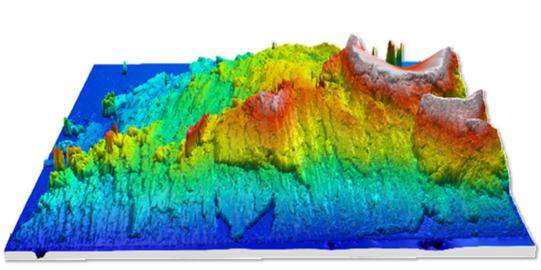

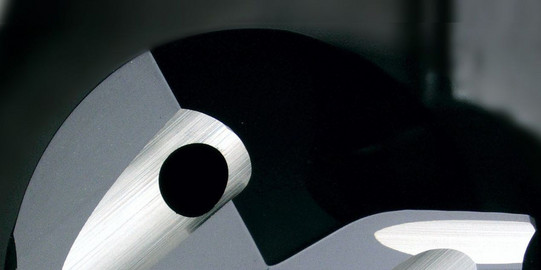

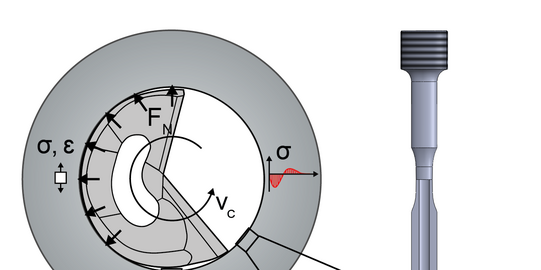

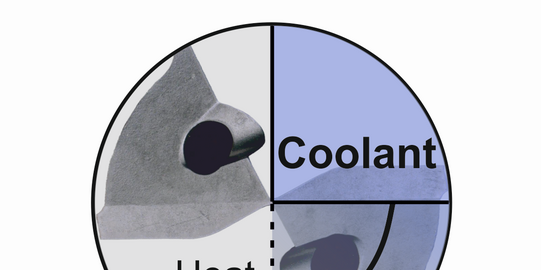

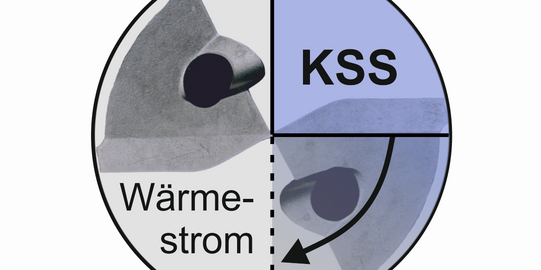

Fundamental Investigations on the Frictional Contact in the Working Zone in Machining Processes

Working Group Machining of Innovative Steels

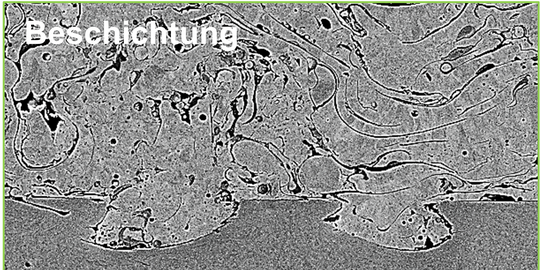

Characterisation and Modelling of the Wear Behaviour of Coated Cemented Carbide Tools Used for Turning a Hard to Machine Steel

Holistic Development and Characterisation of an Efficient Manufacturing of Detachable Joints for Aluminium and Magnesium Lightweight Materials

Fundamental Investigations of Micro Single-Lip Deep Hole Drilling of Challenging Drilling Situations

Vibration Reduction during Turning and Milling of Lightweight Materials with Tool Holders Produced by Laser Beam Melting

Investigations on Optimisation of the Cutting Edge of Twist Drills for the Machining of the High Temperature Resistant Nickel-Base Alloy Inconel 718

Investigations on the Influence of Machining and Sulphur Content on the Fatigue Strength of the Quenched and Tempered Steel 42CrMo4+QT

Geometrically Defined Surface Structuring for the Form-Locked Bonding of Thermal Sprayed Coatings

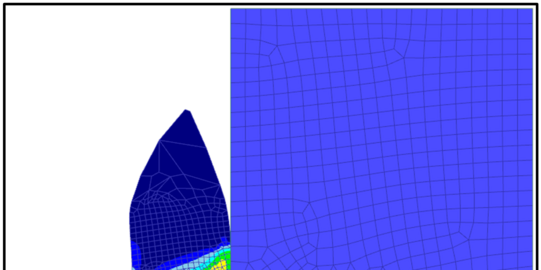

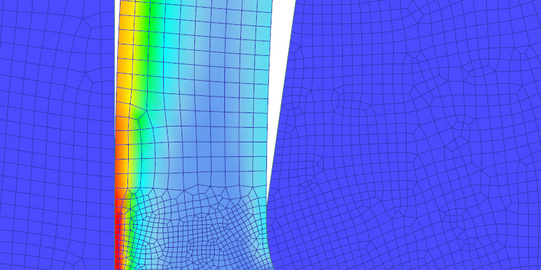

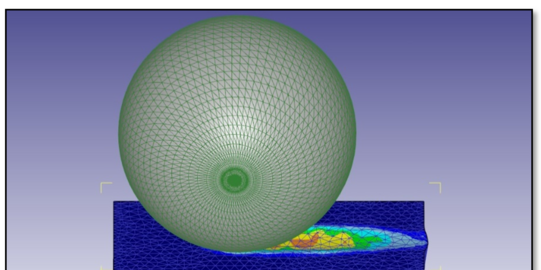

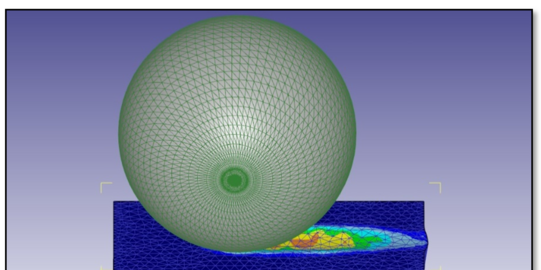

Efficient Modelling of Chip Formation in Orthogonal Cutting Based on Isogeometric Analysis and Modern Methods for Material Characterisation

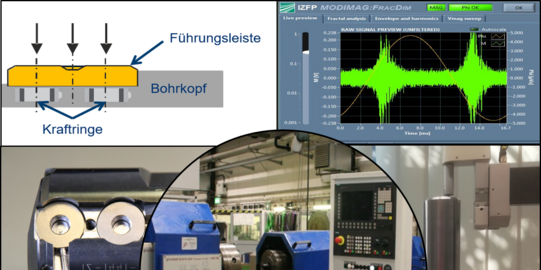

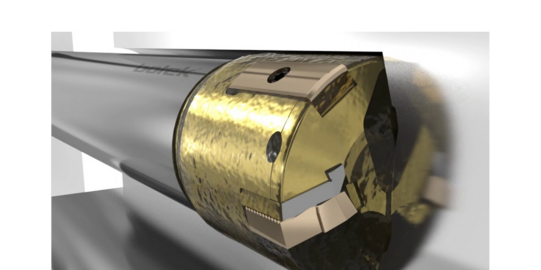

Process-Integrated Measuring and Control System for the Determination and Reliable Generation of Functionally Relevant Properties in Surface Edge Zones during BTA Deep Hole Drilling

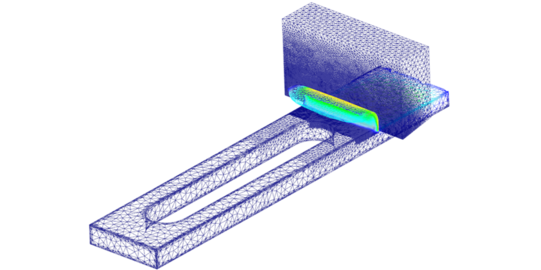

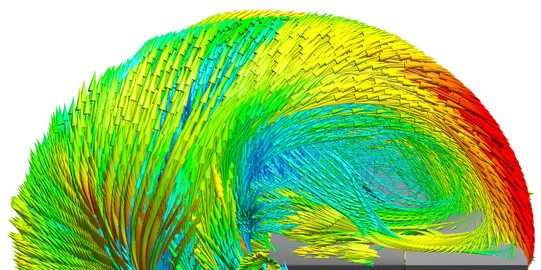

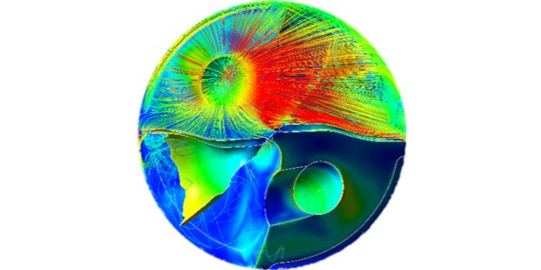

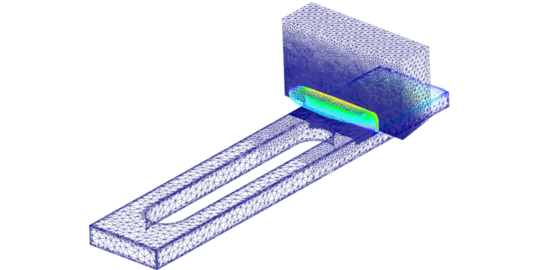

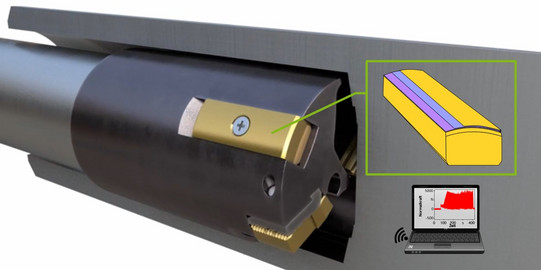

Modelling of the Cooling Lubricant Distribution during Single-Lip Deep Drilling with Consideration of Chip Transport by Means of CFD and SPH/DEM Simulation for Tool and Process Optimisation

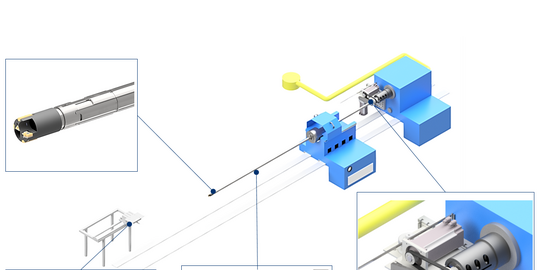

Research and Development of a Mechatronic Tool System fort he Compensation of Straightness Deviation in BTA Deep Hole Drilling

Lightweight and vibration reduced hybrid FRP-metal drill tubes with structure-integrated sensor technology for BTA deep hole drilling processes

Restriction of the Chip Thickness Deviations for Stabilising the Chip Formation of High Strength Metals

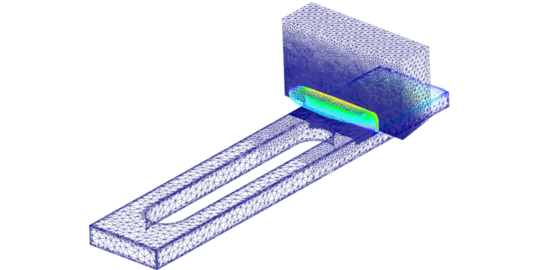

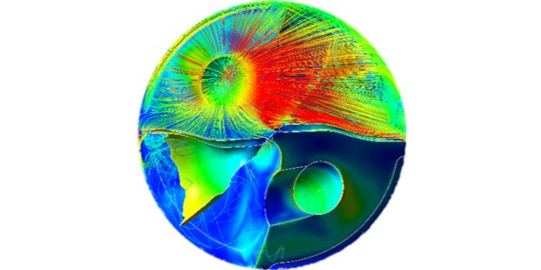

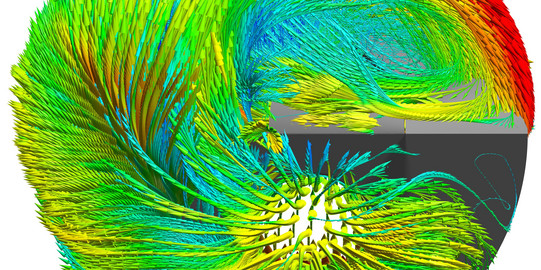

SPP 2231 FluSimPro - Coupled mechanical and fluid dynamic simulation methods to realize efficient production processes

Simulation and optimisation of the coolant flow to reduce thermal tool load during discontinuous drilling of Inconel 718

Tool and Process Optimization for efficient Ejector Deep-Hole Drilling-Processes using Smoothed Particle Hydrodynamics (SPH)

SPP 2231 FLUSIMPRO: Fully coupled fluidstructure-contact simulations to understand the processes in the contact zones during lubricatedorthogonal cutting

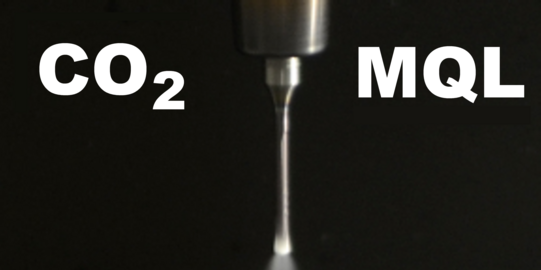

Fundamental investigations on the development of a single-phase CO2-lubricant solution to support deep-hole drilling processes for difficult to cut materials by using a cryogenic CO2 snow-lubricant jet

Development and implementation of a concept for the use of a low temperature emulsion in the drilling of Inconel 718

Qualification of burnishing of additively manufactured components for the production of functional surfaces

Arbeitskreis Zerspanung innovativer Stahlwerkstoffe

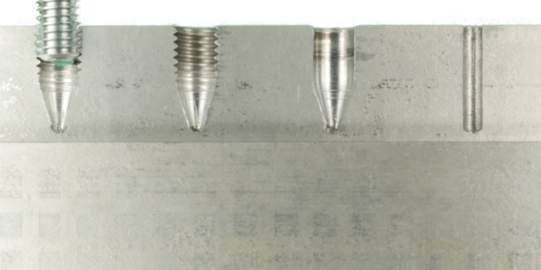

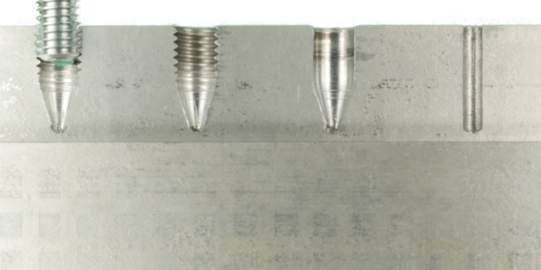

Basic Technological Investigation of a New High-Performance Process for the Production of Internal Threads and Microstructure-Based Characterization of their Performance

Flexible internal turning at any machining depth

Arbeitskreis Zerspanung innovativer Stahlwerkstoffe

Arbeitskreis Zerspanung innovativer Stahlwerkstoffe

Charakterisierung und Modellierung des Verschleißverhaltens beschichteter Hartmetallwerkzeuge bei der Drehbearbeitung eines schwer zerspanbaren Stahlwerkstoffes

Ganzheitliche Entwicklung und Charakterisierung einer effizienten Herstellung lösbarer Fügestellen für Aluminium- und Magnesium-Leichtbauwerkstoffe

Grundlagenuntersuchungen zum Mikroeinlippentiefbohren bei anspruchsvollen Anbohrsituationen

Schwingungsreduzierung bei der Dreh- und Fräsbearbeitung von Leichtbaumaterialien durch den Einsatz strahlgeschmolzener Werkzeugaufnahmen

Untersuchungen zur Optimierung der Schneidengestalt von VHM-Wendelbohrern für die Bearbeitung von warmfesten Nickelbasislegierungen am Beispiel von Inconel 718

Untersuchungen zum Einfluss der spanenden Bearbeitung und des Schwefelgehalts auf die Schwingfestigkeit des Vergütungsstahls 42CrMo4+QT

Entwicklung eines simulativen Modells zur Einflussanalyse des Kühlschmierstoffes beim Wendeltiefbohren mit kleinen Durchmessern unter Berücksichtigung der Spanbildung zur Optimierung der Werkzeug- und Prozessgestaltung für die Bearbeitung von Ti-6Al-4V

Geometrisch bestimmte Oberflächenstrukturierung zur formschlüssigen Anbindung thermisch gespritzter Schichten

Effiziente Modellierung der Spanbildung im orthogonalen Schnitt durch Verwendung isogeometrischer Analyse und moderner Methoden der Materialcharakterisierung

Prozessintegriertes Mess- und Regelungssystem zur Ermittlung und sicheren Generierung von funktionsrelevanten Eigenschaften in Oberflächenrandzonen beim BTA-Tiefbohren (im SPP 2086)

Grundlegende Untersuchungen zum Reibungskontakt in der Wirkzone bei der spanenden Bearbeitung

Charakterisierung und Modellierung des Verschleißverhaltens beschichteter Hartmetallwerkzeuge bei der Drehbearbeitung eines schwer zerspanbaren Stahlwerkstoffes

Ganzheitliche Entwicklung und Charakterisierung einer effizienten Herstellung lösbarer Fügestellen für Aluminium- und Magnesium-Leichtbauwerkstoffe

Grundlagenuntersuchungen zum Mikroeinlippentiefbohren bei anspruchsvollen Anbohrsituationen

Schwingungsreduzierung bei der Dreh- und Fräsbearbeitung von Leichtbaumaterialien durch den Einsatz strahlgeschmolzener Werkzeugaufnahmen

Untersuchungen zur Optimierung der Schneidengestalt von VHM-Wendelbohrern für die Bearbeitung von warmfesten Nickelbasislegierungen am Beispiel von Inconel 718

Untersuchungen zum Einfluss der spanenden Bearbeitung und des Schwefelgehalts auf die Schwingfestigkeit des Vergütungsstahls 42CrMo4+QT

Entwicklung eines simulativen Modells zur Einflussanalyse des Kühlschmierstoffes beim Wendeltiefbohren mit kleinen Durchmessern unter Berücksichtigung der Spanbildung zur Optimierung der Werkzeug- und Prozessgestaltung für die Bearbeitung von Ti-6Al-4V

Geometrisch bestimmte Oberflächenstrukturierung zur formschlüssigen Anbindung thermisch gespritzter Schichten

Effiziente Modellierung der Spanbildung im orthogonalen Schnitt durch Verwendung isogeometrischer Analyse und moderner Methoden der Materialcharakterisierung

Prozessintegriertes Mess- und Regelungssystem zur Ermittlung und sicheren Generierung von funktionsrelevanten Eigenschaften in Oberflächenrandzonen beim BTA-Tiefbohren (im SPP 2086)

Grundlegende Untersuchungen zum Reibungskontakt in der Wirkzone bei der spanenden Bearbeitung

Modellierung der Kühlschmierstoff- verteilung beim Einlippentiefbohren unter Berücksichtigung des Spantransports mittels CFD- und SPH/DEM-Simulation zur Werkzeug- und Prozessoptimierung

Entwicklung und Erforschung eines mechatronischen Werkzeugsystems zur Kompensation des Mittenverlaufs beim BTA-Tiefbohren

Leichte und schwingungsdämpfende hybride FVK-Metall-Rohre mit strukturintegrierter Sensorik für BTA-Tiefbohrprozesse

Gezielte Begrenzung der Spandickenschwankung zur Stabilisierung der Spanbildung bei höherfesten Metallen

SPP 2231 FluSimPro - Gekoppelte mechanische und fluid-dynamische Simulationsmethoden zur Realisierung effizienter Produktionsprozesse

Simulation und Optimierung der KSS-Strömung zur Reduzierung der thermischen Werkzeugbelastung bei der diskontinuierlichen Bohrbearbeitung von Inconel 718

Werkzeug- und Prozessentwicklung für effiziente Ejektortiefbohrprozesse mittels Smoothed Particle Hydrodynamics (SPH)

SPP 2231 FLUSIMPRO: Voll gekoppelte Fluid-Struktur-Kontakt-Simulationen zum Verständnis der Vorgänge in den Kontaktzonen beim Orthogonalschnitt unter KSS

Grundlegende Untersuchungen zur Entwicklung einer einphasigen CO2-Schmierstofflösung für eine gezielte kryogene Minimalmengenschmierung beim Tiefbohren von schwer zerspanbaren Werkstoffen

Entwicklung und Implementierung eines Konzepts zum Einsatz einer Tieftemperaturemulsion (TTE) in der Bohrbearbeitung von Inconel 718

Qualifizierung des Glattwalzens von additiv gefertigten Bauteilen zur Erzeugung von Funktionsflächen

FLIBB - Flexibles Innendrehen in beliebiger Bearbeitungstiefe

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/a/1/csm_Wendel_Tiefbohrer_51a08eea1c.jpg)