Grinding Technology

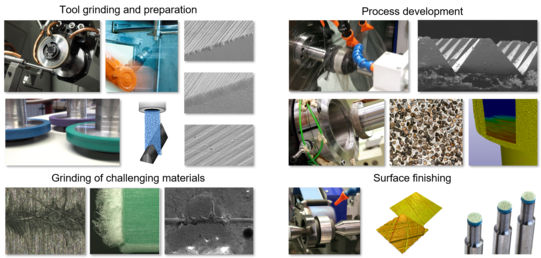

The division ”Grinding Technology“ focuses precision machining such as grinding, finishing, and abrasive blasting. The work covers research and development and, furthermore, consulting and service. The competences include face-, profile- and shape grinding as well as cylindrical grinding and tool grinding processes, also including preparation processes of cutting tools. The introduction of grinding processes for new materials and process combinations are constant challenges. Regarding this, the division “Grinding Technology” offers high-level machinery, equipment and competence to succeed in these tasks. Current research addresses the grinding of composite materials and unreinforced thermoplastics.

State-of-the-art measurement equipment is used to analyse and to optimise the grinding processes. This comprises topography analysis as well as the analysis of thermomechanical load. Changes of the surface layer can be detected by metallographic methods. The development of simulations based on commercial FEA tools and our own geometric-kinematical tools can provide further information about the processes and the results to expect from geometrically complex grinding processes. The work of the division “Grinding Technology” takes place in close cooperation with the other divisions of the ISF and our partners in industry and research.

Projects

Multi-Scale Analysis of the Material Separation Mechanisms in Grinding of Unreinforced Thermoplastics

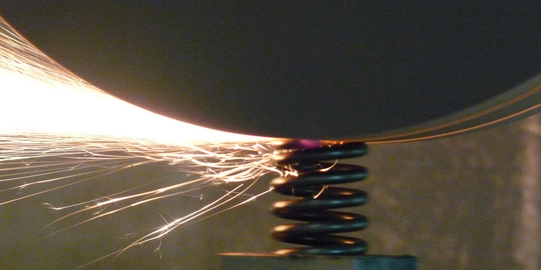

Development of a grinding and dressing strategy for economical grinding of the spring ends of helical compression springs

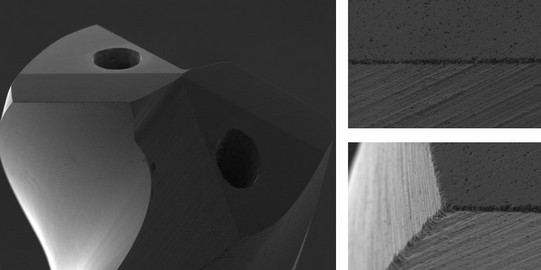

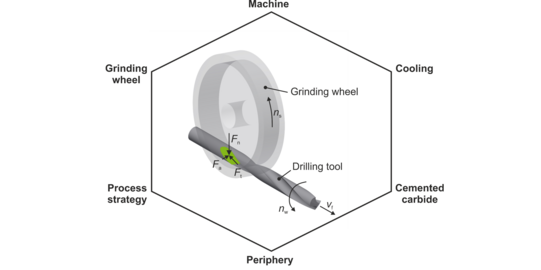

Complete Preparation of Complex Micro Cutting Tools (MikroPräp)

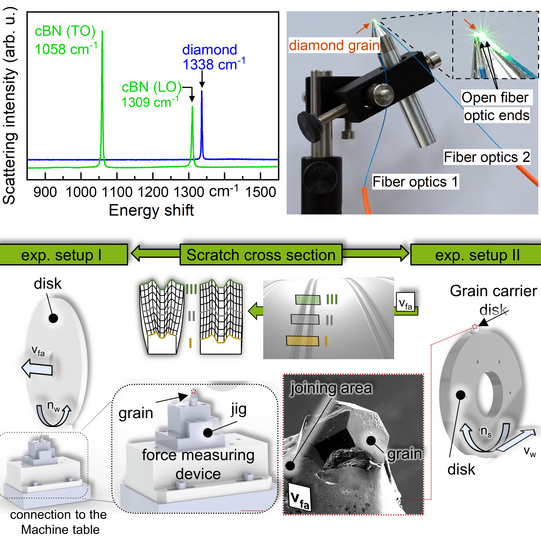

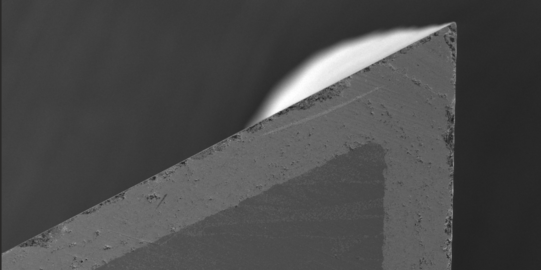

Determination of the microscopic wear mechanisms and operational suitability of diamond and cBN for the precision machining of hardened steel under variation of the thermomechanical load using multiscale measurement methods

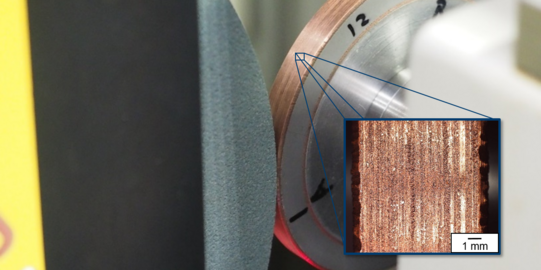

Grinding of cemented carbide with significantly increased cutting speed

Advanced Processing of Additively Manufactured Parts (AD-PROC-ADD)

Fundamental Analysis of Surface Finishing Using Flexible Foams Coated with Diamonds

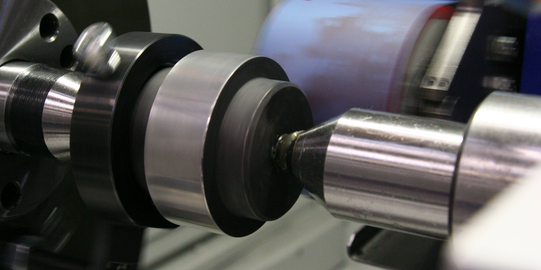

Simulation-Based Design of High-Performance Internal Grinding Processes

Analysis and Qualification of HVOF-WC-Co-Coated Cutting Parts in order to Substitute Sintered Cemented Carbide Cutting Materials

Analysis of a Simulation Approach to Model the Material Removal when Preparing Cutting Edge with Wet Abrasive Jet Machining

Simulation-based tool and process design for microfinishing with metal-bonded honing tools

Prototypical development of a sensory tool holder for in-situ process monitoring for high-speed internal cylindrical grinding

Analysis of the Cold Gas Spraying for the Production of CBN-Metal-Composite Coatings and their Qualification for Application as Grinding Tools

Advanced Processing of Additively Manufactured Parts II (Ad-Proc-Add II)

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)