Analysis of a Simulation Approach to Model the Material Removal when Preparing Cutting Edge with Wet Abrasive Jet Machining

Current investigations reveal that the performance of cutting tools is significantly improvable when preparing the cutting edges. The average cutting edge rounding, utilised for quantifying the size of the rounding, and the form-factor as an indicator for the orientation of the rounding describe the resulting micro-shape of the cutting edge after the preparation. The control of both parameters enables the set-up of the tool’s cutting edge with a targeted and application-oriented shape. In this regard, wet abrasive jet machining offers flexible possibilities to prepare the cutting edge. However, the process control is very challenging since a great number of interacting process parameters influences the wet abrasive jet machining results. Until now, there is no sufficient knowledge of interactions of these parameters. Thus, in order to achieve a defined cutting edge micro-shape, wet abrasive jet machining mostly requires a considerable effort to set up a new process.

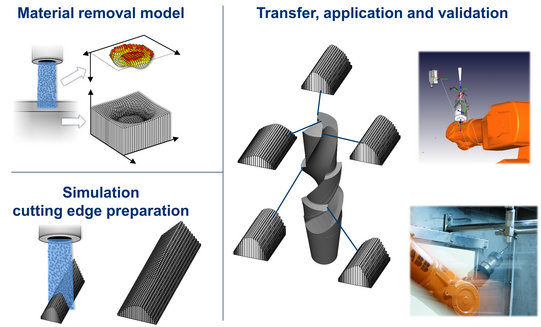

The scientific objective of this research project, with the short title “StrahlSim”, is the development of an efficient model to simulate the material removal when using wet abrasive jet machining with respect to the cutting edge preparation. In this context, fundamental knowledge of interrelationship between the abrasive jet and the material removal at the cutting edge has to be gained and considered for the generation of the numerical model. Especially the comprehension of the interactions of the process parameters are of high relevance in this project to predict the micro-shape of the prepared cutting edge due to the application of the simulation.

With respect to preliminary investigations at the Institute of Machining Technology, the simulation of material removal using a dexel-based method is proved to be expedient. In this context, the wet abrasive jet machining has to be understood as a material removal process which influences the spatial discretised cutting edge in iterative time steps. The development and the validation of the appropriate model takes place in three steps. Initially, the acting abrasive jet has to be characterised in order to generate a parameterisable model for the material removal. The second step comprises the advancement and the validation of the simulation to investigate the material removal when simulating the preparation of idealised cutting edges. In the third step, the application and the optimisation of the simulation for the preparation of complex cutting tools are in the focus of the investigations. By the successful completion of the project, the interactions of process parameters are understood and the developed model is applicable to predict the cutting edge micro-shape when applying wet abrasive jet machining.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)