Development of a grinding and dressing strategy for economical grinding of the spring ends of helical compression springs

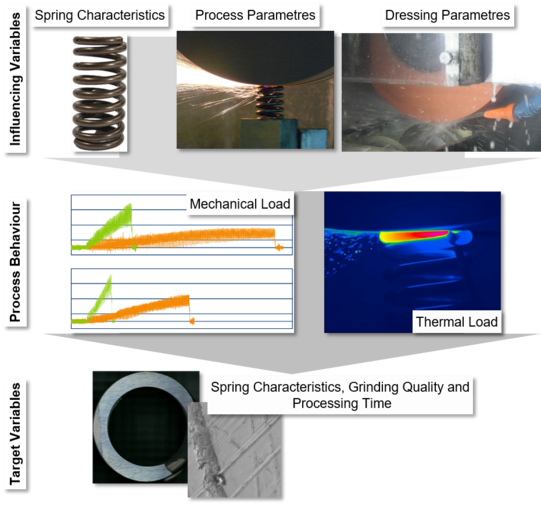

Helical compression springs are used in numerous end products in a wide range of variants and quantities. To ensure perfect operation and a long service life of the helical compression springs, the mechanical load must be applied in the axial direction. For this purpose, the spring ends are often ground flat. However, when considering the entire manufacturing chain of these helical compression springs, the grinding of the spring ends accounts for 40 to 60% of the total costs, which is a significant proportion of the manufacturing costs. In addition, basic scientific knowledge regarding the influence of the process variables of spring end grinding on helical compression springs is not sufficiently documented despite a history of more than 100 years.

The aim of the project is to achieve short cycle times and a high quality of the ground springs with high process reliability by designing the process strategy for spring end grinding and an adapted dressing strategy. The knowledge is to be recorded in the form of recommendations for action in order to optimise the cost- and time-intensive process step, taking into account the high-quality requirements of helical compression springs.

Firstly, the implementation of a test facility with integrated measurement technology is a central task. In addition to targeted process development and a suitable dressing strategy, the interactions of the spring geometry and process parameters on the quality characteristics of the spring are emphasised. The findings are transferred to various industrial framework conditions in order to finally develop general recommendations for action.

The intended results are aimed at companies, predominantly SMEs, in various sectors. The main benefit is the realisation of the manufacturing process for helical compression springs with reduced main and secondary times, which enables a faster and more flexible response to changing specifications while maintaining the same level of quality.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)