Analysis and Qualification of HVOF-WC-Co-Coated Cutting Parts in order to Substitute Sintered Cemented Carbide Cutting Materials

High-performance cutting tools generally consist of sintered solid cemented carbide, mostly based on tungsten carbide and cobalt. To produce the macro geometry of shank tools, such as drills or milling cutters, carbide blanks are ground in various operations. This results in long machining times and sometimes considerable amount of material removal as well. The shortage of tungsten and the minor diversified supplier base for this raw material make economic production more difficult and motivate the testing of alternative concepts in the field of cutting materials. One option is to join cemented carbide tips to a base body. However, the example of accordingly designed sawing tools shows that this production route is very complex due to the necessary production steps of basic body preparation, joining and grinding. It is therefore necessary to identify and research further technically, economically and ecologically profitable alternatives with regard to cutting material concepts.

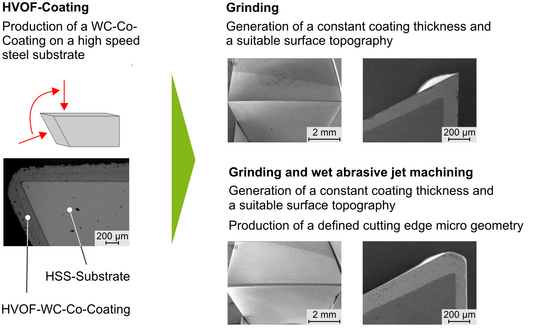

In this context, the investigation and qualification of HVOF-WC-Co-coated cutting parts for the substitution of sintered solid carbide is being carried out within this project. The substrate is a hardened high-speed steel. Within this research project, one focus of the investigations is on the coating specific properties as well as the adjustment and processing of the HVOF-WC-Co coating for use as an alternative cutting material on the cutting part. Furthermore, fundamental analysis on the interrelationships between coatings, cutting edge preparation and application behaviour of coated, ground and prepared cutting edges are carried out. Due to the interdisciplinary character of the project, a cooperation will take place with the Institute of Materials Engineering of the TU Dortmund University. The aim of the project is to develop the necessary fundamentals to replace carbide or carbide-tipped cutting tools with thermally sprayed, specifically adjusted and prepared WC-Co coatings on tool steel bases.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)