Fundamental investigations on the development of a single-phase CO2-lubricant solution to support deep-hole drilling processes for difficult to cut materials by using a cryogenic CO2 snow-lubricant jet

Efficient chip evacuation and heat removal plays an important role in machining of nickel based alloys, e.g. Inconel 718. Furthermore, an increasing demand for more efficient propulsion systems leads to a rising application of components made from hard to cut materials. The characteristics of materials which are used for instance in aircraft and motor vehicle engines lead to high demands for production systems. In particular, a poor heat dissipation combined with a high ductility, hardness and heat resistance of the workpiece material decrease chip breakability and lead to high thermal and mechanical loads of workpiece and tool materials.

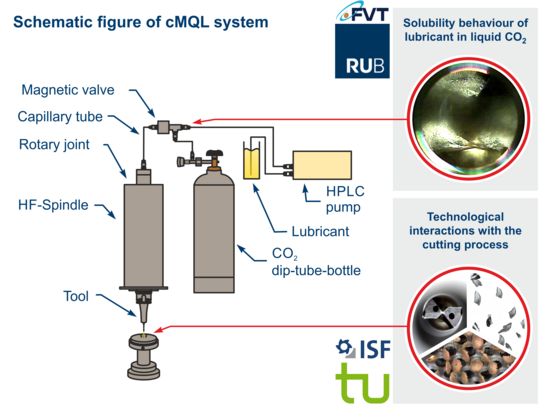

This research project will focus on the promising approach to improve the chip evacuation and heat dissipation using cryogenic minimum quantity lubrication (cMQL). Thereby, a small amount of lubricant is injected into a liquefied carbon dioxide (CO2) stream to realize a cooling and lubricating effect. For this technique, it is necessary to use lubricants which can be dissolved in small quantities in liquefied CO2 to prevent a separation of lubricant and CO2. There is a lack of knowledge in interaction between lubricants which are used in manufacturing processes and liquefied CO2 despite the fact that by using this technology, the advantages of conventional MQL and wet machining can be combined without providing high pressure technologies.

In the field of machining technologies, chip formation, surface integrity, tool life and wear mechanisms while drilling Inconel 718 will be key issues in this research project. For fluid mechanics, phase equilibrium of selected lubricants with liquefied CO2, their solution kinematics and behavior of the solution during the phase change liquid-gaseous will be examined.

Results of this research project will be used to gain general knowledge about mechanisms using cMQL. Furthermore, based on these results optimization of machining processes with respect to economic and ecologic aspects is focused. Therefore, effects of cMQL on tool life, workpiece and process quality will be observed. To characterize the application behaviour, established methods of destructive and non-destructive material testing, which were developed to examine chip formation and transport in deep drilling processes, will be applied. Furthermore, to investigate solution behavior of lubricants in liquefied CO2, methods for determining phase behavior of the solution, flow kinematics and snow jet formation (atomization) will be investigated.

Thus, by combining expertise in the fields of production and process engineering of the involved institutes, a new methodology to apply cMQL will be developed in this interdisciplinary research project to significantly enhance process limits of MQL technique. Hence, with cMQL it will be possible to use advantages of both, MQL and flood cooling for drilling processes of hard to cut materials in challenging dimensions.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/a/1/csm_Wendel_Tiefbohrer_51a08eea1c.jpg)