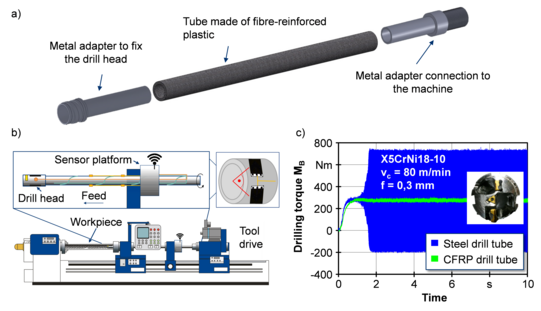

Lightweight and vibration reduced hybrid FRP-metal drill tubes with structure-integrated sensor technology for BTA deep hole drilling processes

BTA deep hole drilling is a process to manufacture bore holes with high length-to-diameter ratios. However, the required tool lengths lead to an increased tendency of the tool system to vibrate. Strong torsional vibrations during drilling, which occur mainly when machining high-alloy materials, lead to increased wear of the cutting edges and guide pads as well as to a reduced bore hole quality. One way to improve the dynamic behaviour is the use of drilling tubes made of fibre-reinforced plastics (FRP). The vibration damping effect resulting from the heterogeneous structure of glass or carbon fibres and the polymeric matrix material has a positive effect on the wear behaviour and the bore hole accuracy. Due to the typically high component costs, the associated increase in process reliability is also a major advantage.

Based on promising preliminary investigations with a CFRP prototype (see figure), a hybrid FRP drill tube with structure-integrated sensor technology is therefore to be developed in this cooperation project between the Institute of Machining Technology (ISF), the Leibniz Institute of Polymer Research Dresden (IPF) and the Fraunhofer Institute for Nondestructive Testing (IZFP). In addition to the experience gained from basic investigations on BTA deep hole drilling and on the production, application and metrological monitoring of metal-CFRP lightweight structures, the cooperation with the companies carbovation, BGTB and Kaiser Maschinenbau und Zerspanungstechnik ensures the support and influence of the expertise of industrial partners from the development, design and production of the drill tubes to the validation under industrial conditions. In order to qualify the FRP drill tube for industrial use, the development of the FRP drill tubes focuses not only on the direct influence on the deep hole drilling process and thus on tool wear and bore hole quality, but also on the material-specific properties of the fibre composite (laminate structure, coolant influence, hybrid connecting elements) and the sensor-based recording of the loads acting in the composite. The use of fibre-reinforced plastics for tool systems requires investigations of the interactions of the matrix and the fibres with other machine components, e.g. in the area of sealing points or contact points on the damping system of the deep hole drilling machine, as well as with coolant lubricants and chips. Furthermore, for the application of structure-integrated sensor technology, the fibre winding process has to be developed with regard to the connection of the sensor fibres with the least possible influence on the fibre composite.

Comprehensive experimental and simulation-supported investigations on vibration optimisation and on the adaptation of the laminate structure to the machining process are carried out within the project. Corrosion processes in direct contact between fibres and metal require the development of hybrid joining systems for the permanent bonding of metallic components to the FRP tube. With the help of a data line to sensors in the drill head and sensors in the laminate of the drill tube, the process-parallel acquisition of important process variables and critical load cases and thus a condition monitoring of the tool system are investigated.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/a/1/csm_Wendel_Tiefbohrer_51a08eea1c.jpg)