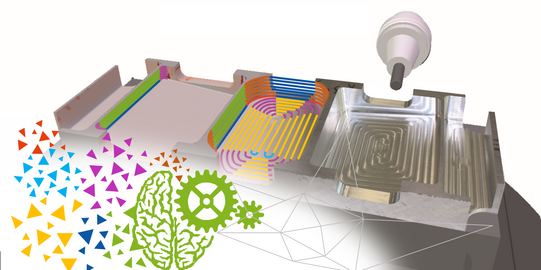

Simulation and Process Design

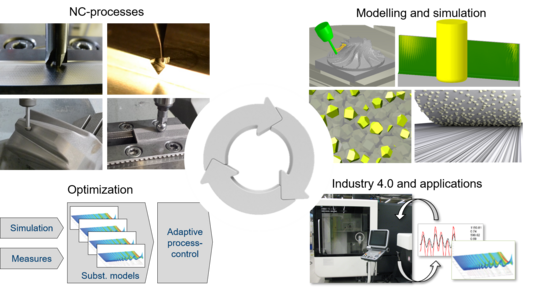

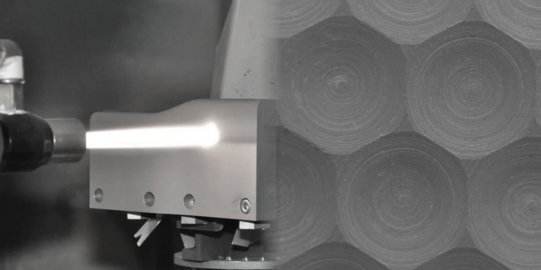

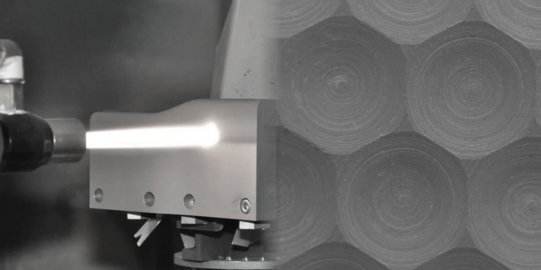

The RG Simulation and Process Design focuses on the simulation-based analysis and optimisation of NC machining processes with defined and undefined cutting edges (Fig.).

Basic investigations, e.g. the machining of hardened high-speed steel, are complemented by the development of innovative processes for structuring freeform surfaces using milling and grinding processes as well as the analysis of additive and subtractive process chains.

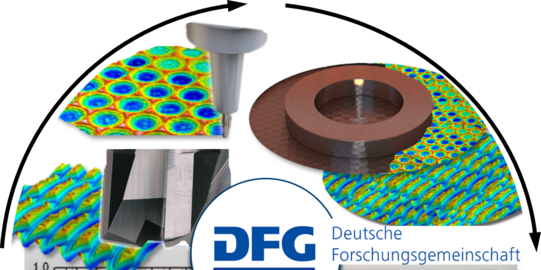

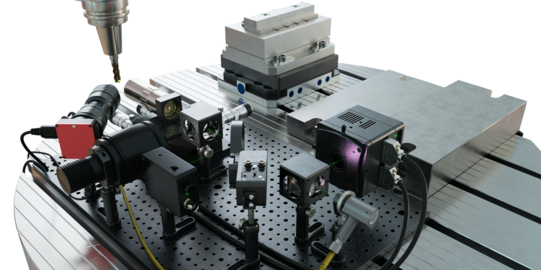

In cooperation with the RG “Virtual Machining” at the Chair of Software Engineering, one of the main research topics is the development of process simulation systems for the analysis and optimisation of machining processes. Regarding for example the simultaneous multi-axis micro- and macromachining of complex structures, e.g. for the mould and die production or the aircraft industry, a simulation system for the analysis of the changing engagement conditions during the NC milling of complex free formed surfaces and the resulting effects is developed. For instance, the loads on the milling tool, complex vibration effects, thermomechanical deformations, and tool wear are investigated in various research works. The modelling and analysis of regenerative vibrations resulting from the interaction of the machining process and the dynamic behaviour of the tool-workpiece-machine-system is one of the main research areas. In addition to the milling simulation, models for grinding and honing are developed to predict the resulting surface topographies.

In conclusion, the potential of process simulations, whose application area comprises detailed analysis of the machining process at the cutting edge, the design of fixture systems and machine tool concepts, and the utilisation during the factory planning process, is investigated in different projects of fundamental research and industry-related cooperation.

Projects

Development of a process chain accelerated manufacturing process for the production of die-cast mold inserts based on a simulation-based methodology and resource-efficient recycling approaches

Fundamental investigations on the effect of structured functional surfaces of milling tools regarding process dynamics

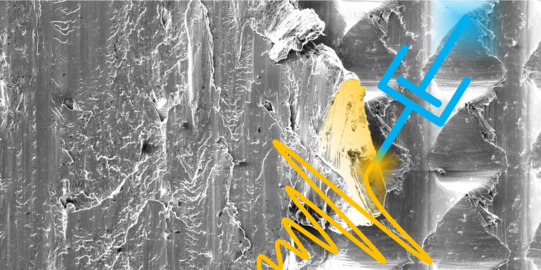

Effects and interactions for interface and cutting-edge conditioning in hard mircomachining

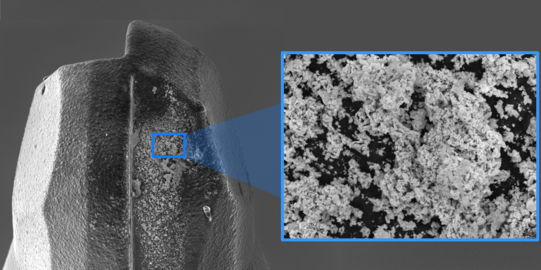

Process Parameter Correlated Characterisation of the Corrosion Fatigue Behaviour of Post-Treated ZnAl-Coated Arc-Sprayed Systems

Modelling of the Axis Position-Dependent Process Dynamics for the Simulation-Based Optimisation of the NC Milling of Freeform Surfaces

Functionalisation of Tool Topographies for Material Flow Control and Tool Life Optimisation (CRC/TCRC 73 SP T07)

Simulation-Based Design of High-Performance Internal Grinding Processes

Fundamental investigations on stabilizing damping effects in milling processes by using functionally structured peripheral cutting edges

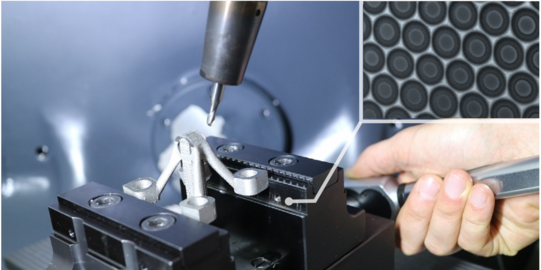

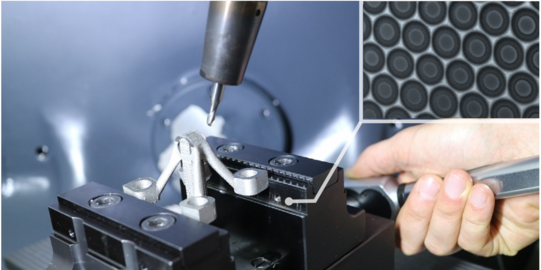

Biologized Clamping Technology (BioClamp)

CoatingStruc – Innovative Hybrid Manufacturing P rocess of Textured, Thermally Sprayed Surface Systems to Improve Friction Coefficients by up to 10%

Fundamental investigations on disturbing the regenerative effect in milling processes through the targeted design of tools with asymmetric dynamic properties

Process and Tool Development for Micromilling of Cemented Carbides

Entwicklung eines prozesskettenverkürzenden Herstellungsverfahrens für die Fertigung von Druckgussformeinsätzen auf Basis einer simulationsgestützten Methodik und ressourceneffizienten Recyclingansätzen

Grundlagenuntersuchung zum Einfluss einer Funktionsflächenstrukturierung von Fräswerkzeugen auf die Prozessstabilität

Wirkmechanismen und Wechselwirkungen zur Grenzflächen- und Schneidkanten-konditionierung in der Mikrohartbearbeitung

Prozessparameterkorrelierte Charakterisierung des Korrosionsermüdungsverhaltens nachbehandelter lichtbogengespritzter ZnAl-Schichtsysteme

Modellierung der achsstellungsabhängigen Prozessdynamik zur simulationsgestützten Optimierung der NC-Fräsbearbeitung von Freiformflächen

Funktionalisierung von Werkzeug- topografien zur Materialflusssteuerung und Standzeitoptimierung (SFB/TRR 73 Transferprojekt T07)

Simulationsbasierte Auslegung von Hochleistungs-Innenrundschleifprozessen

Biologisierte Spanntechnik (BioSpann)

CoatingStruc – Innovativer, hybrider Herstellungsprozess texturierter, thermisch¬gespritzter Oberflächensysteme zur Verbesserung von Reibungskoeffizienten um bis zu 10%

Grundlagenuntersuchung zur Vermeidung des Regenerativeffekts in Fräsprozessen durch gezielte Auslegung von Werkzeugen mit asymmetrischen dynamischen Eigenschaften

Learning based clustering of streamed process data for the efficient modelling and prediction of characteristics in milling processes based on the integration of domain knowledge – ClusterSim

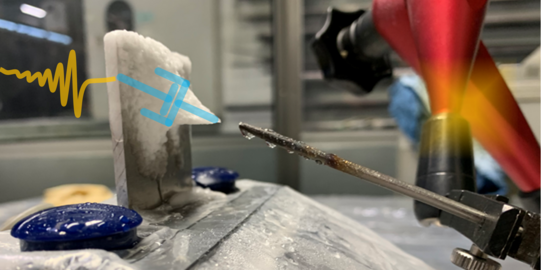

Basic Investigation into the Use of Cryogenically Generated Additive Support Structures and Damping Elements to Stabilize the Milling Process when Machining Thin-Walled Components

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/6/9/csm_AG_SimPro_Eyecatcher_1920p--_5f288a9cd4.jpg)