Modelling of the Axis Position-Dependent Process Dynamics for the Simulation-Based Optimisation of the NC Milling of Freeform Surfaces

The constantly growing requirements and the rising number of variants in production technology, especially in tool and mould manufacturing, often require the production of small batch sizes or individual parts. Simulation systems can be used in the development of manufacturing processes in order to shorten the planning and start-up phases. Especially the machining of complex workpieces with freeform surfaces requires a high planning effort.

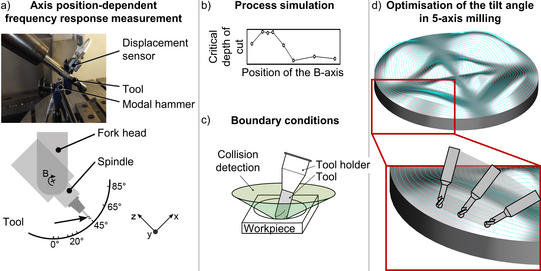

A method for the finishing of freeform surfaces is 5-axis milling, which is usually carried out with spherical or toroidal milling cutters. The requirements for surface quality and dimensional accuracy of these milling processes are high, resulting in a high complexity of the NC path planning. The design of 5-axis processes also requires consideration of numerous effects and influences on the process behaviour. Influencing factors are, for example, the process forces, axis positions as well as the dynamic and kinematic properties of the system. In particular, the consideration of the axis position-dependent dynamic behaviour is insufficient in existing simulation systems. Therefore, the modelling of the axis position-dependent flexibility of the machine-tool system is important for process optimisation.

In this project, the axis position-dependent modal properties of different machining centres are investigated by means of impact tests for measuring frequency response functions. Afterwards, the measurement results are converted into models of the dynamic behaviour of the system. Applying these models, process simulations can be used to design stable machining processes.

In cooperation with the Chair XIV Virtual Machining of the Department of Computer Science at TU Dortmund University, a geometric physically based process simulation will be extended in order to identify axis positions leading to stable processes. Taking the acceleration behaviour of the feed axes and possible collisions into account, a subset of valid process parameters is identified. Thus, 5-axis milling processes can be designed with a high process stability while avoiding collisions.

In order to investigate the influence of the axis position on the process stability for different machine concepts, the 5-axis machining centres DMG HSC 75 and Heller FT4000 are analysed. These machine tools differ in terms of their kinematics and their size. Therefore, they represent a wide range of applications for the method developed. Based on the examination results, conclusions are to be drawn on the required number of supporting points of statistical models used for calculating the axis position-dependent dynamic behaviour of the machine tools. By using the process simulation to adapt the tilt angle for machining a validation workpiece, exemplary NC paths are adapted for both machine concepts and the applicability of the developed approach is validated.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/6/9/csm_AG_SimPro_Eyecatcher_1920p--_5f288a9cd4.jpg)