Functionalisation of Tool Topographies for Material Flow Control and Tool Life Optimisation (CRC/TCRC 73 SP T07)

The transfer project presented here comprises the improvement of die filling during warm and hot forming by local modification of the friction coefficients on the die side. This project is based on the results of two research periods of the CRC/Transregio 73 with the subprojects B2 and B3. The previous developments were carried out with the focus on a cold forming process. The aim of the project is to investigate whether the previous findings on material flow control can be transferred to hot forming of sheet metal.

The first task is to investigate the influence of the previous methods, which record the production of different surface modifications by micro and high-feed milling, on warm processes and to adapt them to these. So far, the structuring processes have only been investigated on the tool materials defined in the CRC/TCRC 73, which are not used in hot forming. One goal is to investigate the transferability of these surface modifications to hot work steels. To this end, it is necessary to identify the optimum process parameter settings for the respective production process (micromilling and high-feed milling). The aim is to achieve a flawless surface finish and a dimensional and shape deviation of the structure of < 3 µm with sufficient surface quality at the same time.

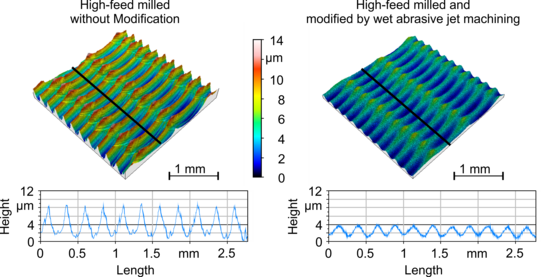

The transfer of the findings from cold forming provides the necessary basis for the planned investigations. The aim is to analyse the material flow caused by the structures on the basis of tribological investigations and to adapt it to the combined sheet bulk metal hot forming by modifying the structure design in order to achieve a higher improvement potential. The development of strategies to increase the wear resistance of the structures is also the focus of the investigations. In this context, a wet abrasive jet machining process is used for the post-treatment of the structured surfaces (Fig.).

This requires the development of suitable strategies. Under real conditions, selected surface modifications are to be evaluated with regard to their possible operation time. With the completion of the project, it should also be possible to successfully use surface structures for material flow control in the field of warm and hot forming.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/6/9/csm_AG_SimPro_Eyecatcher_1920p--_5f288a9cd4.jpg)