Robert Schmidt M.Sc.

Kontakt

Anschrift

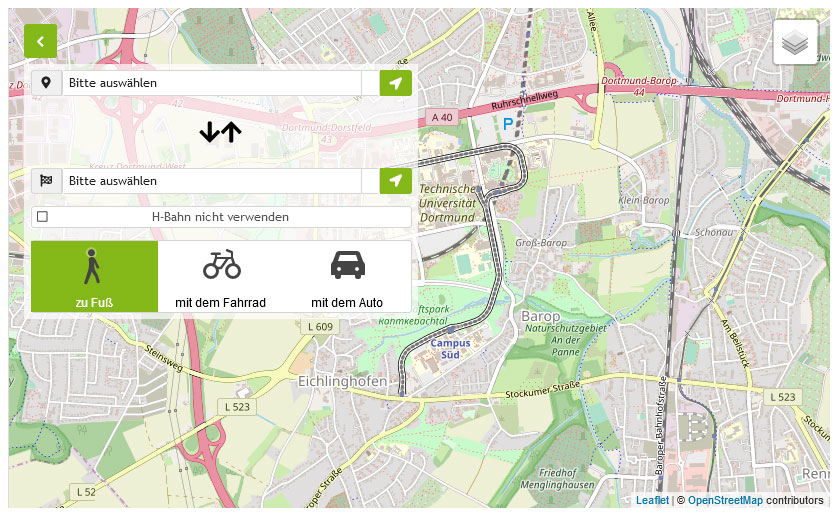

Institut für Spanende Fertigung

Technische Universität Dortmund

Baroper Straße 303

44227 Dortmund

Büro

MB III Raum 2.026

Telefon

0231 755-5822

Aufgabenbereiche

- BTA-Tiefbohren

- Werkzeugentwicklung

Weitere Informationen

Robert, S.

Untersuchung zum Einfluss des thermomechanischen Belastungskollektivs auf die Oberflächenkonditionierung beim BTA-Tiefbohrprozess

Dissertation, Technische Universität Dortmund, Vulkan Verlag, Essen, 2024, ISBN 78-3-8027-8928-1, http://dx.doi.org/10.17877/DE290R-24527

Biermann, D.; Schmidt, R.; Strodick, S.; Walther, F.; Zabel, A..

Numerical modelling of the BTA deep hole drilling process,

7th CIRP Conference on Surface Integrity, Procedia CIRP 123 (2024), S. 470-475, https://doi.org/10.1016/j.procir.2024.05.082

Strodick, S.; Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Automatic diagnosis and thickness determination for white etching layers in deep drilled steels based on thresholding and machine learning algorithms,

7th CIRP Conference on Surface Integrity, Procedia CIRP 123 (2024), S. 30-35, https://doi.org/10.1016/j.procir.2024.05.008

Schmidt, R.

Einfluss der Prozessdynamik auf die Oberflächenkonditionierung beim BTA-Tiefbohren

Begleitinformationen zur Tagung und Versuchsfeldbesichtigung VDI-Fachtagung Präzisions- und Tiefbohren aktuell 2024, 12.-13.03.2024, Dortmund

Strodick, S., Schmidt, R., Donnerbauer, K., Rozo Vasquez, J., Zabel, A., Macias Barrientos, M., Biermann, D., Walther, F.:

Subsurface conditioning in BTA deep hole drilling for improved component performance.

Prod. Eng. Res. Devel. (2024). https://doi.org/10.1007/s11740-023-01252-0

S. Strodick, D. Steffens ,F. Walther, R. Schmidt, A. Zabel, D. Biermann

Towards reliable micromagnetic detection of white etching layers in deep drilled quenched and tempered steels

5. Niedersächsisches Symposium Materialtechnik (2023), https://doi.org/10.21268/20230711-9

R. Schmidt, S. Strodick, F. Walther, A. Zabel, D. Biermann

Tool design for the integration of piezoelectric and micro magnetic sensors to realize in-process measurements in BTA deep hole drilling

33rd CIRP Design Conference, Procedia CIRP 119 (2023), S. 408-413, https://doi.org/10.1016/j.procir.2023.06.196

Strodick, S.; Hühn, F. R.; Schmidt, R.; Biermann, D.; Zabel, A.; Walther, F.:

Evolution of the residual stress state in BTA deep drilled components under quasi-static and cyclic loading.

ICRS 11, Proceedings of the 11th International Conference on Residual Stresses, (2023) 1-8, https://hal.science/hal-04022501

R. Schmidt, S. Strodick, F. Walther, A. Zabel, D. Biermann

Investigation of BTA analogy experiments to determine the influence of different cutting edge designs on the surface integrity, 16th CIRP ICME, Procedia CIRP 118 (2023), S 549-554, https://doi.org/10.1016/j.procir.2023.06.094

Schwersenz, A.; Erli, R.; Nawal, K. - Magnetic Sense GmbH, Öhringen (Germany), Biermann, D.; Michel, S.; Schmidt, R.; Wiesweg, L. - TU Dortmund University, Dortmund (Germany)

Contactless Torque Measurement in BTA/STS Deep Hole Drilling by using the Villari Effect – a first Proof of Concept, Proceedings SMSI 2023, Poster, S. 320-321, doi: 10.5162/SMSI2023/P21

Weng, J.; Schmidt, R.; Saelzer, J.; Sicking, M.; Zhuang, K.; Biermann, D.; Schmid, L.:

Towards understanding the wear mechanisms of turning with FreeTurn, Wear 526-527 (2023)

https://doi.org/10.1016/j.wear.2023.204951.

Strodick, S.; Schmidt, R.; Brause, L.; Zabel, A.; Biermann, D.; Walther, F.:

Mikromagnetische Charakterisierung der Bohrungsintegrität.

wt Werkstattstechnik online 112, 11/12 (2022) 757-761. https://doi.org/10.37544/1436–4980–2022–11–12–31

Schmidt, R.; Nickel, J.:

Beeinflussung der Randzonenintegrität tiefgebohrter Bauteile

MM Maschinenmarkt ,129, (2023) 1-2, S. 38-39

Gerken, J; Schmidt, R.; Biermann, D.; Fuss, M.

Tool and process development for chambering bores with non-circular contour in highly stressed workpieces

International Journal of Mechatronics and Manufacturing Systems 14 (2021) 289. 10.1504/IJMMS.2021.121245

Schmidt, R.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Influence of the cutting edge on the surface integrity in BTA deep hole drilling - part 1: Design of experiments, roughness and forces

6th CIRP Conference on Surface Integrity, Procedia CIRP 108 (2022), S. 329-334, doi: 10.1016/j.procir.2022.03.055

Strodick, S.; Schmidt, R.; Biermann, D.; Zabel, A.; Walther, F.

Influence of the cutting edge on the surface integrity in BTA deep hole drilling - part 2: Residual stress, microstructure and microhardness

6th CIRP Conference on Surface Integrity, Procedia CIRP 108 (2022), S. 276-281, doi: 10.1016/j.procir.2022.03.047

Schmidt, R.; Brause, L.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Measurement and analysis of the thermal load in the bore subsurface zone during BTA deep hole drilling

55th CIRP Conference on Manufacturing Systems (CMS 2022), Procedia CIRP 107 (2022), S. 375-380, doi: 10.1016/j.procir.2022.04.061

Strodick, S.; Schmidt, R.; Gerdes, L.; Zabel, A.; Biermann, D.; Walther, F.

Impact of cutting parameters on the mechanical properties of BTA deep drilled components under quasi-static compression

Procedia CIRP, 103 (2021), S. 207-212, doi: 10.1016/j.procir.2021.10.033

Huang, X.; Schmidt, R.; Strodick, S.; Walther, F.; Biermann. D.; Zabel, A.

Simulation and modeling of the residual stress state in the sub-surface zone of BTA deep-hole drilled specimens with eigenstrain theory

Procedia CIRP 102, 2021, S. 150-155, doi: 10.1016/j.procir.2021.09.026

Zabel, A.; Strodick, S.; Schmidt, R.; Walther, F.; Biermann, D.; Wegert, R.; Eisseler, R.; Möhring, H.-C.; Guski, V.; Schmauder, S.

Oberflächenkonditionierung beim Tiefbohren - Teil 2.

wt Werkstattstechnik online, 111 (2021) 03, S. 118-123. doi: 10.37544/1436-4980-2021-03-26

Zabel, A.; Strodick, S.; Schmidt, R.; Walther, F.; Biermann, D.; Wegert, R.; Eisseler, R.; Möhring, H.-C.; Guski, V.; Schmauder, S.

Oberflächenkonditionierung beim Tiefbohren - Teil 1.

wt Werkstattstechnik online, 111 (2021) 1, S. 52-58. doi: 10.37544/1436-4980-2021-01-02-56

Strodick, S.; Berteld, K.; Schmidt, R.; Biermann, D.; Walther, F.; Zabel, A.

Influence of cutting parameters on the formation of white etching layers in BTA deep hole drilling

tm - Technisches Messen, 69 (2020), S. 1-9, doi: /10.1515/teme-2020-0046

Schmidt, R.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Analysis of the functional properties in the bore sub-surface zone during BTA deep-hole drilling

Procedia CIRP 88, (2020), S. 318-323, doi: 10.1016/j.procir.2020.05.055

Schmidt, R.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Influence of the process parameters and forces on the bore sub-surface zone in BTA deep-hole drilling of AISI 4140 and AISI 304 L

Procedia CIRP, 87 (2020), S. 41-46, doi: 10.1016/j.procir.2020.02.010

Strodick, S.; Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Evaluation of surface integrity after BTA deep-hole drilling of AISI 4140 by means of Barkhausen noise analysis

In: Proceedings of the 13th International Conference on Barkhausen Noise and Micromagnetic Testing, 23.9.-26.9. 2019, Prag, Tschechien

Schmidt, R.; Gerken, J. F.; Fuß, M.; Biermann, D.

Analysis of contour accuracy and process forces using a chamber-boring-system

Modern Machinery (MM) Science Journal, Special Issue on HSM 2019 15th International Conference on High Speed Machining, (2019), S. 3316-3322, doi: 10.17973/MMSJ.2019_11_2019087

Strodick, S.; Walther, F.; Schmidt, R.; Zabel, A.; Biermann, D.

Analyse des Eigenspannungszustands in der Bohrungsrandzone tiefgebohrter Probekörper aus 42CrMo4+QT und X5CrNi18-10

Werkstoffprüfung 2019 - Fortschritte in der Werkstoffprüfung für Forschung und Praxis, Hrsg.: Christ, H.-J., INVENTUM GmbH, ISBN 978-3-88355-418-1, (2019), S. 287-292

Biermann, D.; Schmidt, R.; Strodick, S.; Walther, F.; Zabel, A..

Numerical modelling of the BTA deep hole drilling process,

7th CIRP Conference on Surface Integrity, 14-17.05.2024, Bremen

Schmidt, R.; Brause, L..; Strodick, S.;Walther, F. ; Biermann, D.; Zabel, A.

An investigation on the dynamic behavior of the BTA deep hole drilling process – increasing the process stability and sustainability,

18th CIRP ICME Conference, 10-12.07.2024, Naples, Italy.

Schmidt, R.

Untersuchung zum Einfluss des thermomechanischen Belastungskollektivs auf die Oberflächenkonditionierung

beim BTA-Tiefbohrprozess, Promotionsvortrag, 07.08.2024, Dortmund

Strodick, S.; Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Automatic diagnosis and thickness determination for white etching layers in deep drilled steels based on thresholding and machine learning algorithms,

7th CIRP Conference on Surface Integrity, 14-17.05.2024, Bremen

Schmidt, R.; Sicking, M.; Gerken, J. F.; Rinschede, T.

Entwicklungen und Herausforderungen beim Einsatz innovativer Tiefbohrverfahren

Wissensforum Zerspanung, 21.-22.11.2023, Würzburg

Schmidt, R.

Einfluss der Prozessdynamik auf die Oberflächenkonditionierung beim BTA-Tiefbohren

VDI-Fachtagung Präzisions- und Tiefbohren aktuell 2024, 12.-13.03.2024, Dortmund

Schmidt, R.; Sicking, M.; Rinschede, T.

Entwicklungen und Herausforderungen beim Einsatz innovativer Tiefbohrverfahren

Wissensforum Zerspanung, 21.-22.11.2023, Würzburg

R. Schmidt, S. Strodick, F. Walther, A. Zabel, D. Biermann

Tool design for the integration of piezoelectric and micro magnetic sensors to realize in-process measurements in BTA deep hole drilling

33rd CIRP Design, 17-19.05.2023, Sydney, Australia

Strodick, S. (Sp.); Steffens, D.; Schmidt, R.; Biermann, D.; Zabel, A.; Walther, F.:

Towards reliable micromagnetic detection of white etching layers in deep drilled quenched and tempered steels.

5. Symposium Materialtechnik des Clausthaler Zentrums für Materialtechnik, Clausthal-Zellerfeld, 23.-24. Feb. (2023).

Strodick, S. (Sp.); Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F. :

Micromagnetic monitoring of the surface integrity for BTA deep hole drilling.

ICBM 14, 14th International Conference on Barkhausen Noise and Micromagnetic Testing, Stockholm, Sweden, 27.-30. Sept. (2022)

Schwersenz, A.; Erli, R.; Nawal, K. - Magnetic Sense GmbH, Öhringen (Germany), Biermann, D.; Michel, S.; Schmidt, R.; Wiesweg, L. - TU Dortmund University , Dortmund (Germany)

Contactless Torque Measurement in BTA/STS Deep Hole Drilling by using the Villari Effect – a first Proof of Concept

Schmidt, R.; Nickel, J.; Strodick, S.; Baak, N.; Walther, F.; Zabel, A.; Biermann, D.

Beeinflussung der Funktionseigenschaften tiefgebohrter Bauteile durch gezielte Einstellung der Randzonenintegrität

Wissensforum Zerspanung, 23.-24.11.2022, Würzburg

Schmidt, R.; Strodick, S.; Walther, F.; Zabel, A.; Biermann, D.

Investigation of BTA analogy experiments to determine the influence of different cutting edge designs on the surface integrity

16th CIRP Conference on Intelligent Computation in Manufacturing Engineering, 13.-15.07.2021, Golf von Neapel, Italien

Schmidt, R.; Brause, L.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Measurement and analysis of the thermal load in the bore sub-surface zone during BTA deep hole drilling

55th CIRP Conference on Manufacturing Systems, 29.06.-01.07.2022, Lugano

Schmidt, R.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A.

Influence of the cutting edge on the surface integrity in BTA deep hole drilling - part 1: Design of experiments, roughness and forces

6th CIRP Conference on Surface Integrity, 08.-10.06.2022, Lyon

Strodick, S.; Schmidt, R.; Biermann, D.; Zabel, A.; Walther, F.

Influence of the cutting edge on the surface integrity in BTA deep hole drilling - part 2: Residual stress, microstructure and microhardness

6th CIRP Conference on Surface Integrity, 08.-10.06.2022, Lyon

Strodick, S.; Schmidt, R.; Gerdes, L.; Zabel, A.; Biermann, D.; Walther, F.

Impact of cutting parameters on the mechanical properties of BTA deep drilled components under quasi-static compression

CIRPe 2021, 9th CIRP Global Web Conference, 26.-28.10.2021, online

Strodick, S. (V.); Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Influence of cutting parameters on surface integrity in BTA deep hole drilling of steel components

ICEAF 6, 6th International Conference of Engineering Against Failure, 23.-25.06.2021, Online

Schmidt, R.; Strodick, S.; Zabel, A.; Biermann, D.; Walther, F.

Influence of the process parameters and forces on the bore sub-surface zone in BTA deep-hole drilling of AISI 4140 and AISI 304 L

5th CIRP International Conference on Conference on Surface Integrity (CSI), 1-5.6.2020, Web conference

Strodick, S.; Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Micro-magnetic assessment of functional properties in the sub-surface zone of deep drilled AISI 4140 and 304L steels

MSE 2020, Materials Science and Engineering, 22-25.09.2020 , Web conference

Biermann, D.; Zabel, A.; Schmidt, R.; Iovkov, I.

Control of surface integrity in BTA deep hole drilling

Technical Presentation in STC "C". CIRP Winter Meeting, 20.02.2020, Paris

Strodick, S.; Schmidt, R.; Zabel, A.; Biermann, D.; Walther, F.

Evaluation of surface integrity after BTA deep-hole drilling of AISI 4140 by means of Barkhausen noise analysis

13th International Conference on Barkhausen Noise and Micromagnetic Testing, 23.-26.9.2019, Prag, Tschechien

Schmidt, R.; Gerken, F.; Fuß, M.; Biermann, D.

ANALYSIS OF CONTOUR ACCURACY AND PROCESS FORCES USING A CHAMBER-BORING-SYSTEM

15th International Conference on High Speed Machining Prague, 08.10.2019

Schmidt, R.; Biermann, D.; Zabel, A.; Strodick, S.; Walther, F.

Generierung von funktionsrelevanten Eigenschaften in Oberflächenrandzonen beim BTA-Tiefbohren

WerkstoffWoche 2019, 18.-20.09.2019, Dresden

Schmidt, R.; Strodick, S.; Zabel, A.; Walther, F.; Biermann, D.

Analysis of the functional properties in the bore sub-surface zone during BTA deep-hole drilling

13th CIRP International Conference on INTELLIGENT COMPUTATION IN MANUFACTURING ENGINEERING, 17.07.-19.07.2019, Ischia, Naples, Italy

Schmidt, R.

Bearbeitung von Titanlegierungen: Einflussgrößen, Werkzeugverschleiß, Prozesskräfte

Moderne Hochleistungswerkstoffe spanend bearbeiten, 09.04. - 10.04.2019, Dortmund