Dr. Jian Weng

Kontakt

Anschrift

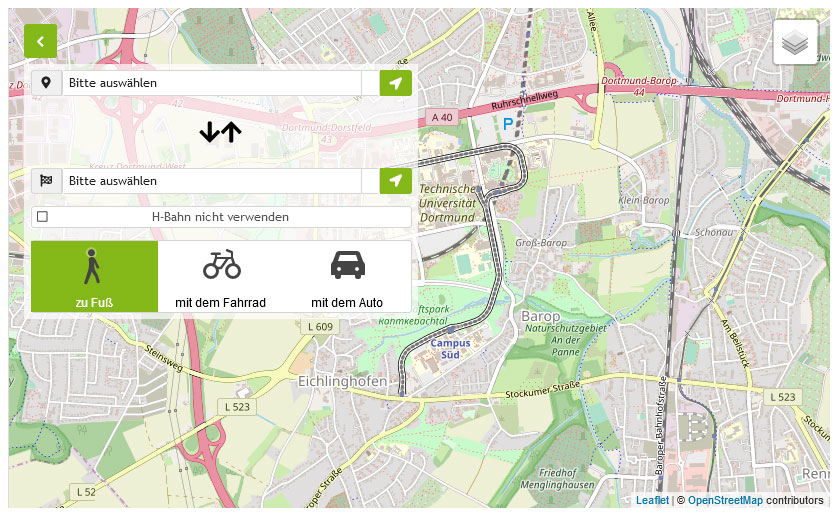

Institut für Spanende Fertigung

Technische Universität Dortmund

Baroper Straße 303

44227 Dortmund

Büro

MB III Raum 2.017

Telefon

0231 755-

jian.weng@tu-dortmund.de

Aufgabenbereiche

- Cutting mechanics

- Surface integrity

- Free turning

Weitere Informationen

Prediction of mechanisms and residual stress for curved surface turning considering the effect of tool micro geometry

Weng, J.; Saelzer, J.; Berger, S.; Zhuang, K.; Bagherzadeh, A.; Budak, E.; Biermann, D.;

Analytical and experimental investigations od rake face temperature considering temperature-dependent thermal properties

Journal of Materials Processing Technology, 314 (2023), 117905. https://doi.org/10.1016/j.jmatprotec.2023.117905

Zhuang, K.; Zhou, S.; Zou, L.; Lin, L.; Liu, Y.; Weng, J.; Gao, J.

Numerical investigation of sequential cuts residual stress considering tool edge radius in machining of AISI 304 stainless steel

Simulation Modelling Practice and Theory, 118 (2022) 102525, ISSN 1569-190X,

doi: 10.1016/j.simpat.2022.102525.

Zhuang, K.; Fu, C.; Weng, J.; Hu, C.

Cutting edge microgeometries in metal cutting: a review

The International Journal of Advanced Manufacturing Technology, 116 (2021) 11, S. 2045-2092, ISSN 0268-3768, doi: 10.1007/s00170-021-07558-6.

Weng, J.; Liu, Y.; Zhuang, K.; Xu, D.; M’Saoubi, R.; Hrechuk, A.; Zhou, J.

An analytical method for continuously predicting mechanics and residual stress in fillet surface turning

Journal of Manufacturing Processes, 68 (2021), S. 1860-1879, ISSN 1526-6125,

doi: 10.1016/j.jmapro.2021.07.004

Weng, J.; Zhuang, K.; Xu, D.; M’Saoubi, R.; Zhou, J.

A comprehensive study on cutting mechanisms and surface integrity of AISI 304 when turning a curved surface

Materials and Manufacturing Processes, 36 (2021) 11, S. 1285-1298, ISSN 1042-6914,

doi: 10.1080/10426914.2021.1906893

Weng, J.; Lindvall, R.; Zhuang, K.; Ståhl, J.-E.; Zhou, J.

A machine learning based approach for determining the stress-strain relation of grey cast iron from nanoindentation

Mechanics of Materials, 148 (2020) 103522, ISSN 0167-6636,

doi: 10.1016/j.mechmat.2020.103522

Weng, J.; Zhuang, K.; Zhou, J.; Ding, H.

A hybrid model for force prediction in orthogonal cutting with chamfered tools considering size and edge effect

The International Journal of Advanced Manufacturing Technology, 110 (2020), S. 1367-1384, ISSN 0268-3768, doi: 10.1007/s00170-020-05943-1

Weng, J.; Zhuang, K.; Hu, C.; Ding, H.

A PSO-based semi-analytical force prediction model for chamfered carbide tools considering different material flow state caused by edge geometry

International Journal of Mechanical Sciences, 169 (2019), 105329, ISSN 0020-7403,

doi: 10.1016/j.ijmecsci.2019.105329

Weng, J.; Zhuang, K.; Hu, C.; Zhu, D.; Guo, S.; Ding, H.

A novel approach to thermal modeling based on three-dimensional analysis in turning Inconel 718 with round insert

Journal of Materials Processing Technology, 266 (2019), S. 588-598. ISSN 0924-0136,

doi: 10.1016/j.jmatprotec.2018.11.040

Weng, J.; Zhuang, K.; Zhu, D.; Guo, S.; Ding, H.

An analytical model for the prediction of force distribution of round insert considering edge effect and size effect

International Journal of Mechanical Sciences, 138-139 (2018), S. 86-98, ISSN 0020-7403,

doi: 10.1016/j.ijmecsci.2018.01.024

Weng, J.; Zhuang, K.; Chen, D.; Guo, S.; Ding, H.

An analytical force prediction model for turning operation by round insert considering edge effect

International Journal of Mechanical Sciences, 128 (2017), S. 168-180, ISSN 0020-7403,

doi: 10.1016/j.ijmecsci.2017.04.018