Qualification of burnishing of additively manufactured components for the production of functional surfaces

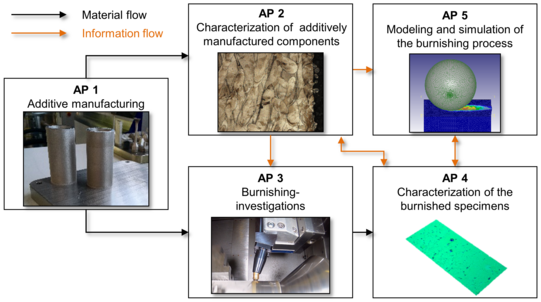

The development of additive manufacturing processes for entire components, individual elements or specific parts, as tool holders is currently one of the most important trends in manufacturing technology and represents a rapidly growing sector. The use of additive manufacturing opens up new possibilities for designers. In this way, parts can be produced that cannot be realized by conventional machining processes or can only be accomplished with considerable effort. A disadvantage of the additive manufacturing processes and especially of the SLM process is the necessity of postprocessing parts in the areas of functional and fitting surfaces in order to achieve the required manufacturing tolerances and surface qualities. This is often done by conventional machining processes such as milling or grinding. Within the scope of this research project, roller burnishing is to be used and qualified as an alternative process for improving the surface quality of additively manufactured components. The advantages of burnishing are that, especially compared with milling, a smaller allowance can be selected for additive production and that, in addition to improving surface roughness, the burnishing process can also increase the hardness by exploiting strain hardening. Due to the smaller allowance, the process time during laser melting can be greatly reduced and metal powder, which is relatively cost-intensive as a raw material, can also be saved. For this purpose, the complete production chain consisting of additive manufacturing, a possibly necessary pre-turning process and burnishing will be analyzed and optimized. In a first step, the additive production of stainless steel 1.4404 is examined in detail. The individual built up angles and their influence on the surfaces and component geometries are compared and characterized. This step is necessary to categorize the components for the subsequent burnishing process. The hollow tubes, classified according to their roughness values, are then machined by roller burnishing. Here, the aim of the process is to achieve the best possible surface quality and thus to replace the otherwise necessary machining post-processing. In addition to the smoothing of the surface, the effect of the increase in hardness in the near-surface edge zone is investigated, which is usually not in the foreground when burnishing is used, but can still be measured due to the process. In addition, structural changes and achievable geometric accuracies over the entire process chain are analyzed and evaluated. Thus, the goal is reached that a production of additive components with subsequent post-processing can be carried out as cost and time optimized as possible. Finally, a model for the simulation of the burnishing process of additive components will be developed in order to be able to predict the achievable surface qualities in the future and to save time and costs.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/a/1/csm_Wendel_Tiefbohrer_51a08eea1c.jpg)