Fundamental Characterization and Analysis of the Lubricating Effect of Quasicrystalline Powders as an Intermediate Medium in the Chip Formation Zone

The use of metalworking fluids is associated with high energy and cost expenditure. This is in contrast to the limited effectiveness of the media used, particularly with regard to the lubricating effect. The main reasons for this are the high normal contact stresses and temperatures in the chip formation zone. This results in the need to research and develop further lubricant formulations that can be used more efficiently and thus save energy and resources. Quasicrystals offer a promising approach here, as they have exceptional tribological properties, which are essentially reflected in low frictional resistance. Due to the high mechanical stability of quasicrystals, these properties can also be expected at high pressures and have also been demonstrated over a very wide temperature range. Preliminary investigations have shown that quasicrystal powder mixed with a conventional metalworking emulsion can significantly reduce frictional resistance in the chip forming zone.

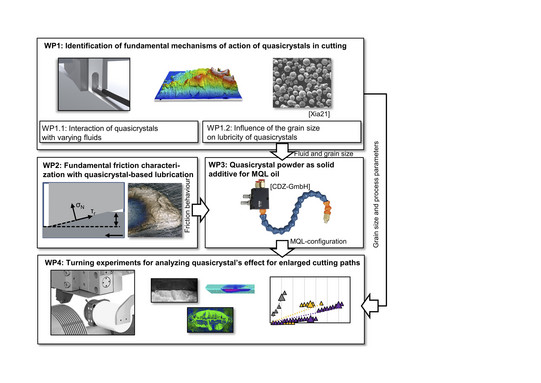

The aim of this project is to investigate the mechanisms of action of the identified relationships and thus lay the foundation for the development of quasicrystal-based lubricants for machining. A work programme to achieve this goal is shown in the figure. Initially, the interaction with various liquid metalworking fluids and the influence of different grain sizes of the quasicrystal powders on the lubricating effect will be investigated in basic orthogonal section studies. In a next step, it is planned to investigate the suitability of the quasicrystals as an additive for oils for minimum quantity lubrication. In addition to the resulting lubricating effect compared to liquids without solid particles, the experiments will also focus on possible challenges in atomizing the media. At the end of the proposed project, it is planned to investigate the influence of friction reduction by quasicrystals on the wear evolution of the tools as part of turning tests. As the progress of wear is strongly temperature dependent, the temperatures on the rake face of the tool are to be measured using an innovative test rig. In comparison to dry machining and cooling lubrication with conventional media, these serve as a further measured variable in order to be able to assess the lubricating effect of the quasicrystals.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/a/1/csm_Wendel_Tiefbohrer_51a08eea1c.jpg)