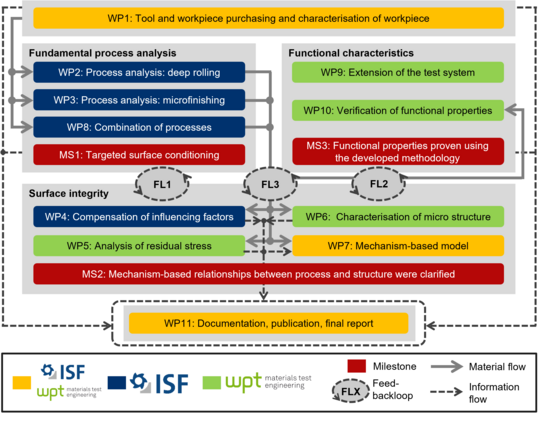

Mechanism-based and functionality-oriented surface conditioning for highly stressed components by combined deep rolling and microfinishing processes

In this fundamental research project, it is planned to investigate the possibilities for the controlled adjustment of the surface integrity of heat-treatable steels with regard to their functionality as contact partners in systems subject to load cycles through mechanical surface conditioning by deep rolling and microfinishing. In the industrial application of large bearings for wind turbine gearboxes, for example, the quenched and tempered steel 42CrMo4 is predominantly used, so that the samples utilized in this project are also made of this material. To further increase the component service life, the bearings are usually additionally edge zone hardened. This thermal edge zone modification represents an additional process step in the conventional production chain.

In this research project, in cooperation with the Chair of Materials Test Technology (WPT), we plan to investigate the possibilities for specifically adjusting the surface integrity of heat-treated steels with regard to their functionality as contact partners in systems subject to alternating loads through mechanical surface conditioning by means of roll hardening and microfinishing.

Against this background, the overriding scientific objective of this project is to use a combination of the deep rolling and microfinishing processes to specifically condition the edge zone state and topography and, compared to the edge zone-hardened component, to achieve improved functional properties, especially for dynamically and tribologically highly stressed components. The results of joint preliminary work already carried out indicate that a combination of the two processes is suitable in principle for reproducible and sustainable edge zone modification, so that the processes are to be fundamentally researched and coordinated accordingly.

In order to qualitatively and quantitatively record process-microstructure-property relationships, a non-destructive method is to be developed to ensure production-related conditioning using microstructure-sensitive micromagnetic sensor technology. This means that, in addition to fundamental investigations of both machining processes, a comprehensive examination of the influence on the component with regard to the properties of residual stress, micro and macro hardness, microstructure and surface topography is necessary. As a result, an elementary sub-goal is to be able to quantify the component properties and thus define suitable target parameters for achieving an appropriate surface integrity. In addition, possibilities must be developed to compensate for potential sources of error within the respective sub-steps with the help of the subsequent processes, which is particularly relevant for industrial applications. The risk of reworking or even rejects can thus be reduced, enabling a resource-efficient design of the process chain.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)