Complete Preparation of Complex Micro Cutting Tools (MikroPräp II)

The preparation of cutting tools in the macro range is already well established in the industrial environment due to the positive influence of the preparation on the application behaviour and in particular on the wear resistance. For micro tools, however, the influence of the preparation on the application behaviour has not yet been sufficiently researched and is therefore the subject of current research. In addition, the interactions between the preparation and coating of microtools are not sufficiently understood. Particular challenges in the field of micro machining are the very small cutting depths and chip thicknesses. Because of this, the knowledge gained from the preparation of macro tools can only be transferred to a limited extent.

From the macro area it is already known that a process-adapted cutting edge design can enable significant increases in performance compared to non-process-adapted edge designs. The preparation and targeted adjustment of cutting edges can make an important contribution to ensuring the competitiveness of tool manufacturing companies. The increasing demand for miniaturised components with high dimensional accuracy requirements, such as in medical technology or tool and mould making, could be accompanied by both an increase in demand and higher quality requirements for micro-machining tools. Even small deviations in the macro and micro shape of the tool can have a significant impact on performance and process reliability.

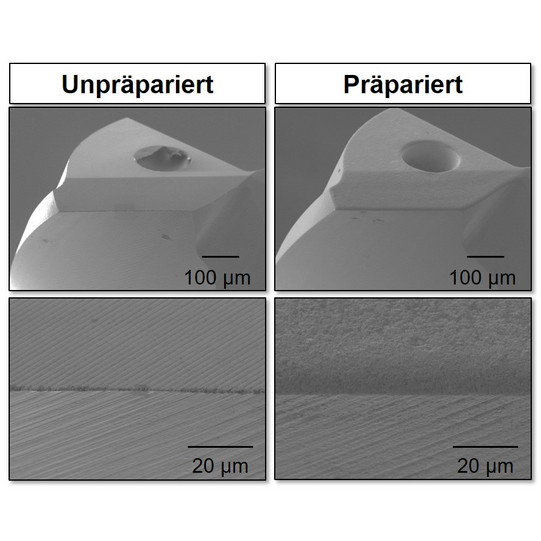

In the case of micro tools, the very low cutting depths that can be achieved in use result in high demands on the tool grinding process in order to minimise chipping, micro defects and concentricity errors, which have a strong negative impact on tool life. Compliance with the increased requirements is associated with higher production costs. Furthermore, in order to meet the high quality requirements, it is necessary to detect and quantify even small deviations in the geometric tool features and tool micro-shape by using measurement and evaluation strategies with high accuracy and good stability. Cutting edge preparation therefore pursues the objective of removing microscopic defects on the tool cutting edges through targeted preparation and adapting the cutting edge micro-shape to the load resulting from the respective machining task. The cutting edge rounding relevant for micro tools therefore requires robust measurement and quantification methods to assess the tool micro-shape in the initial and prepared state.

The previous project (MikroPräp) demonstrated that adapted cutting edge microgeometry can offer considerable potential for increasing the tool life and process stability of micro twist drills. Methods for characterizing the cutting edge rounding were evaluated during the project to meet the changed requirements with reduced diameters. It has been shown that standard measuring devices and methods can also be used to measure the cutting edge shape and surface roughness of the adjacent functional surfaces.

Based on these findings, the aim of the current research project is to increase the performance of micro-cutting tools through efficient cutting edge preparation in combination with adapted process control.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)