Grinding of cemented carbide with significantly increased cutting speed

Flute grinding of cemented carbide tools is usually realized by deep grinding and thus represents the most time-intensive process step in the production of cemented carbide tools. Due to the complex contact situation in the grinding gap, thermal loads are of particular importance. These may cause unfavourable residual stresses, which result among other things due to different coefficients of thermal expansion of the hard material and binder phase and thus are considered to be critical during machining and performance reducing when using the tools. In general, the used circumferential grinding wheel speed is in a moderate range of vc = 15…35 m/s. One approach to increasing productivity and reducing costs in the production of cemented carbide tools is high-speed grinding, which is already established in the field of steel machining. The positive effects of high-speed grinding generally result from reduced single grain loads as well as an improved surface quality due to the more frequently overlapping grinding paths. Challenging in this respect is the increasing thermal load with increasing cutting speed as well as an additionally impeded coolant supply in the effective zone. This supply is made more difficult by an air film surrounding the grinding wheel due to the high circumferential speed of the grinding wheel. At the same time, the coolant supply must be adapted to the high circumferential speed so that sufficient wetting of the grinding wheel is possible.

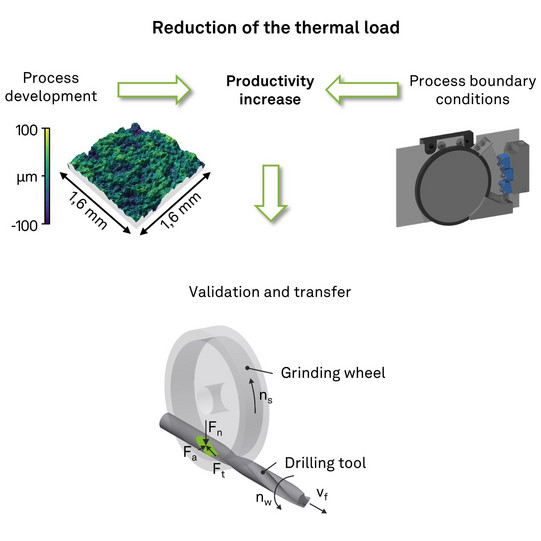

The objective of this research project is therefore to achieve an enhancement in productivity as a result of an increased depth of cut ae and feed rate vf, with significantly increased cutting speed compared to conventional grinding of cemented carbide. In order to achieve these goals, it is essential to optimize the process cooling within the framework of the project so that thermal damages to the substrate can be avoided. At the same time, the energy efficiency of the process and the surface topography of the tools should be improved by increasing the cutting speed. In order to realize the above-mentioned goals, the fundamental interactions with regard to the deep grinding of cemented carbide with significantly increased cutting speed are investigated. Based on this, the thermal loads are reduced on the one hand by designing suitable nozzle concepts with integrated high-pressure coolant supply and on the other hand as a result of adequate conditioning of the grinding wheel topography.

Funding reference:

The IGF project 21687 N "Grinding of cemented carbide with significantly increased cutting speed" of the research association VDW-Forschungsinstitut e.V. is supported by the AiF within the framework of the programme for the promotion of Industrial Collective Research (IGF) by the Federal Ministry for Economics Affairs and Climate Action on the basis of a decision of the German Bundestag.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)