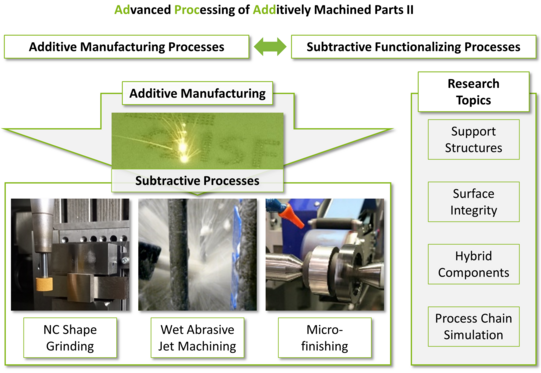

Advanced Processing of Additively Manufactured Parts II (Ad-Proc-Add II)

Due to increasing interest in additive manufacturing processes for metal components, there are several needs for research and development regarding the additive-subtractive manufacturing (ASM) process chain. As in all technological areas, the interest in these processes is also increasing the requirements in terms of quality. For additive manufacturing, this means increased requirements for surface quality as well as dimensions, shape, and position tolerances. Furthermore, AM and the entire ASM process chain must be economically competitive.

The Ad-Proc-Add II project engages with these challenges by investigating the ASM process chain from start to finish. The additive pre-processing will be improved for optimal subsequent subtractive process steps regarding economic factors such as minimal allowances, reduced process forces, optimized support structures, and tool wear. Tweaking of AM parameters will quantify and reveal optimisation potential for surface integrity and enable better control. Moreover, different interrelations between ASM process steps will be investigated to enable a hybrid and flexible combination of different AM processes (DED and PBF-LB/M) and pre-machined workpieces. A holistic view of the ASM chain will be created with the help of numeric additive and subtractive process simulation and data processing so that pre-defined workpiece properties can be achieved directly while providing a minimum of uncertainty. Additionally, to enable advanced optimization potential such as improved toolpath strategies (CAD-CAM optimization) and increased process automation capabilities, an ASM process chain knowledge database prototype, combining multi-sensor data inputs from different process steps, will be developed.

The international project consortium consists of seven research institutions from Germany, Austria and Belgium: IfW - Universität Stuttgart (DE), GFE Schmalkalden (DE), KU Leuven (BE), Thomas More (BE), IFT - TU Wien (AU), Fotec (AU), and the ISF - TU Dortmund University (DE).

The investigations at the ISF focus on influencing the surface integrity of AM workpieces along the ASM process chain. Therefore, the ISF uses a laser powder bed fusion (PBF-LB/M) additive process and investigates the influences of the subtractive processes NC shape grinding, wet abrasive jet machining, and microfinishing.

The findings, insights, prototypes, and experimental results will be presented towards the international public by workshops, practical seminars, publications, website, and exhibition at fairs. The project will be accompanied by a user committee of SMEs from all relevant market sectors: tool manufacturing, additive manufacturing equipment, machine tool manufactures, software and service providers, as well as end-users. The intensive communication with the industrial partners ensures the elaboration of industrially relevant and usable results.

![[Translate to English:] [Translate to English:]](/storages/isf-mb/_processed_/4/8/csm_Schleifscheiben_8bb5d31229.jpg)